Pipeline EquipmentPendantsAVSU ModulesManifoldsTest Equipment & Medical Gas TapeProduct BrochureMedical Air PlantMedical Vacuum PlantAGSS PlantTerminal UnitsAVSUsAlarmsIsolation Valves

NIST Tee AssembliesPressure Reducing SetsStub PipesMedical Gas Hose AssyTwin NIST Manifolds1st Fix Hex NIST ConnectorsLow Vacuum Switch AssyHigh/Low Pressure Switch Assy

NIST Tee Assemblies

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems, and BS EN ISO 18082.

- Provide connection for hose NIST nipples to pipeline.

- Available from 12mm to 28mm, alternative sizes available on request.

- User serviceable non-return valves prevent gas flow when not connected to hose assemblies.

- Supplied with blank NIST cap for protection prior to commissioning.

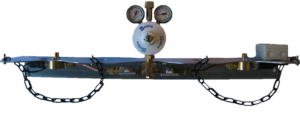

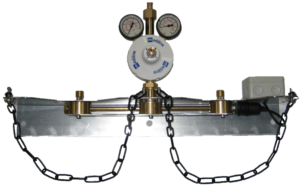

Pressure Reducing Sets

These kits comprise simplex or duplex regulators with pressure gauges, isolation valves, pressure relief valve and copper stub pipes mounted on a backplate.

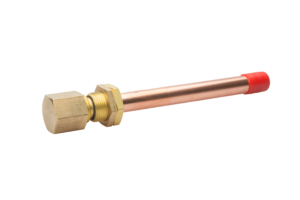

Stub Pipes

We stock a selection of stub pipes with male and female connections suitable for medical and laboratory installations. Please contact us with your requirements.

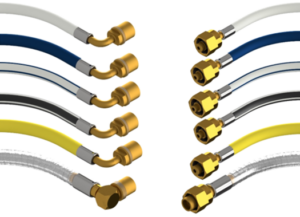

Medical Gas Hose Assy

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 5359, BS EN ISO 18082, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS EN ISO 7396-1 and BS EN ISO 7396-2.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Manufactured using phthalate-free, anti-static PU hose colour coded to BS EN ISO 5359.

- End connector options include NISTs, BS probes and terminal units.

- Different lengths and configurations available to suit all types of pendants and other applications.

- Fully tested and certified prior to despatch.

Twin NIST Manifolds

These kits comprise a brass block c/w two NIST bodies and a NIST nipple & nut.

1st Fix Hex NIST Connectors

These kits comprise a gas specific NIST connector with a 15mm copper stub pipe, blank NIST cap and lock nut.

Low Vacuum Switch Assy

These kits comprise a single Pipeline PSW Block c/w Stub Pipe and Vacuum Switch for monitoring low vacuum in the pipeline and are used in conjunction with an Area Alarm Panel.

High/Low Pressure Switch Assy

These kits comprise a twin Pipeline PSW Block c/w Stub Pipe and Pressure Switches for monitoring high & low pipeline pressure and are used in conjunction with an Area Alarm Panel.

Rigid Pendants

- Rigid Pendants are ceiling mounted fixed columns complete with first fix plate and ceiling shroud, with an epoxy powder coated finish.

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- A maximum of 9 medical gas and AGSS terminal units, complete with BS EN ISO 5359 hose assemblies, can be accommodated within each pendant.

- Each pendant can accommodate a maximum of 8 twin pre-wired electrical sockets.

- Other sockets can be incorporated into the pendant as required, contact us to discuss your project.

Retractable Pendants

- Retractable Pendants are ceiling mounted, height adjustable columns complete with first fix plate and ceiling shroud, with an epoxy powder coated finish.

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- The height to the underside of the pendant can be smoothly and accurately adjusted throughout a 300mm range.

- A maximum of 9 medical gas and AGSS terminal units, complete with BS EN ISO 5359 hose assemblies, can be accommodated within each pendant.

- Each pendant can accommodate a maximum of 8 twin pre-wired electrical sockets.

- Other sockets can be incorporated into the pendant as required, contact us to discuss your project.

Flexible Pendants

- Flexible pendants distribute medical gases and AGSS to the operating table/anaesthetic machine whilst leaving the surrounding area free from trailing hoses.

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- A maximum of 7 medical gas and AGSS terminal units, complete with BS EN ISO 5359 hose assemblies, can be accommodated within each pendant.

AVSU Module with Area Alarm & Pressure SensorsAVSU Module with Pressure Sensors, no Area AlarmAVSU Module, no Pressure Sensors, no Area Alarm

AVSU Module with Area Alarm & Pressure Sensors

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- Available for up to 6 gases.

- Supplied as a pre-piped 1st fix assembly, with copper stub sizes from 22mm to 42mm mounted on a steel backplate for convenient installation.

- Pre-wired pressure sensors and electrical connection boxes on the 1st fix simplify on-site connections for area alarms.

- A white, powder coated 2nd fix fascia complete with individual AVSU doors and area alarm panel is available in surface mounted or semi-flush variants to suit project requirements.

AVSU Module with Pressure Sensors, no Area Alarm

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- Available for up to 6 gases.

- Supplied as a pre-piped 1st fix assembly, with copper stub sizes from 22mm to 42mm mounted on a steel backplate for convenient installation.

- Pre-wired pressure sensors and electrical connection boxes on the 1st fix simplify on-site connections for area alarms.

- A white, powder coated 2nd fix fascia complete with individual AVSU doors is available in surface mounted or semi-flush variants to suit project requirements.

AVSU Module, no Pressure Sensors, no Area Alarm

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- Available for up to 6 gases.

- Supplied as a pre-piped 1st fix assembly, with copper stub sizes from 22mm to 42mm mounted on a steel backplate for convenient installation.

- A white, powder coated 2nd fix fascia complete with individual AVSU doors is available in surface mounted or semi-flush variants to suit project requirements.

Automatic ManifoldsEmergency Reserve ManifoldsManual ManifoldsEmergency Standby ManifoldsVIE Control PanelsPressure Reducing Sets

Automatic Manifolds

These kits comprise an automatic changeover panel with alarm & status monitoring, an isolation & relief valve assy, non-return valve, two manifold headers, two cylinder racks and tailpipes with gas specific cylinder connectors.

Emergency Reserve Manifolds

- Meets the requirements of HTM 02-01 - Medical Gas Pipeline Systems.

- Multi-stage regulator for accurate control up to 500 l/min.

- Pressure switches provided on each cylinder bank, pre-wired to termination box for connection to central alarm system.

- Supplied with tailpipes including cylinder connections to suit local requirements.

- Isolation and pressure relief valve assembly provided with copper stub pipes for connection to distribution and exhaust pipelines.

- 2 x 1 and 2 x 2 configurations as standard, larger sizes available on request.

Manual Manifolds

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- Multi-stage regulator for accurate control up to 500 l/min.

- Header pressure switches provided, pre-wired to termination box for connection to central alarm system.

- Supplied with tailpipes including cylinder connections to suit local requirements.

- Isolation and pressure relief valve assembly provided with copper stub pipes for connection to distribution and exhaust pipelines.

Emergency Standby Manifolds

- Meets the requirements of HTM 2022 - Medical Gas Pipeline Systems.

- Multi-stage regulator for accurate control up to 500 l/min.

- Pressure switch provided on header, pre-wired to termination box for connection to central alarm system.

- Supplied with tailpipes including cylinder connections to suit local requirements.

- Isolation and pressure relief valve assembly provided with copper stub pipes for connection to distribution and exhaust pipelines.

- 2 x 1 and 2 x 2 configurations as standard, larger sizes available on request.

VIE Control Panels

A Plant to Alarm Interface Unit is available for monitoring the alarm status of the VIE system.

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, and BS EN ISO 7396-1.

- Designed to provide flow rates from 1500 – 6000 l/min, with one regulator isolated.

- Duplex regulator assembly for continuity of supply.

- Includes pipeline connections for VIE and standby manifold.

- Piped exit pressure relief valves included for safe discharge outside the plant room.

- Supplied with pressure switches for connection to a plant to alarm interface.

- Mounted in a steel enclosure with window for convenient monitoring of pressure gauges.

- Fully tested and certified prior to despatch.

Pressure Reducing Sets

These kits comprise simplex or duplex regulators with pressure gauges, isolation valves, pressure relief valve and copper stub pipes mounted on a backplate.

Medical Gas Tape

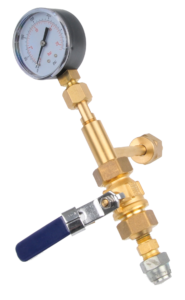

NIST Test Units

- Designed for carrying out tests via NIST connectors outlined in HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- Available with fittings to suit digital manometers or analogue pressure gauges.

- Includes manual isolation/vent valve with lockable handle.

- Universal BS probe version also available.

Product Brochure

Medical Air Plant RangeDuplex Medical Air PlantTriplex Medical Air PlantsQuadruplex Medical Air PlantPentaplex Medical Air PlantHexaplex Medical Air Plant

Medical Air Plant Range

Medical Air Plant Range

P3 manufacture a comprehensive range of air plant for medical air, surgical air and combined medical/surgical air systems.

Key Features and Benefits

- Meets the requirements of HTM 02-01 and HTM 2022 - Medical Gas Pipeline Systems

- Oil injected screw compressors for low noise, vibration free operation as standard

- Duplex, Triplex, Quadruplex, Pentaplex and Hexaplex configurations available

- Oil-free compressors available on request

- Duplex heatless desiccant air dryer including economy circuit

- Electronic transducer-driven HMI controls ensure reliable plant operation

- Plant controls are configured to minimise running costs for end user

- Controls include volt-free N/C contacts for connection to central alarm systems and BMS

- Option for on-board RTX transmitter for connection to SDX-15 central alarm

- Plant includes all interconnecting pipework and wiring

- All plant is fully factory tested and certified prior to despatch

Duplex Medical Air Plant

All of our Medical Air equipment is built to the highest standards of quality and come as standard with the following features:

- All interconnecting Pipework and wiring are included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (SDFM) Screw Duplex Floor Mounted all equipment is mounted on the floor.

- (SDC) Screw Duplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

STANDARD SPECIFICATION

Duplex Medical Air Plant to HTM02-01 and HTM2022 each Compressor after dryer losses sized to meet the DutyTriplex Medical Air Plants

The plant is supplied as a factory assembled and tested unit and is available from a standard range or can be custom built to suit project specific requirements.

Quadruplex Medical Air Plant

Pentaplex Medical Air Plant

Hexaplex Medical Air Plant

AGSS Plants

Phoenix Pipeline Products Limited produces a complete range of simplex and duplex AGSS systems to British Standard HTM02-01. They start with a small flow rate of 390l/m to any size to suit customers requirement. AGSS Plants are manufactured in accordance with Quality Management System BS EN 13485 for medical devices. AGSS Plants are used to extract gases and aerosolized medication from operating rooms, which have been exhaled from the patient to the outside of the hospital protecting operating room staff from long term exposure to these harmful substances.

In the UK, in order to maintain a safe workplace within the Operating room, Occupational Health Set the maximum limit exposure to potentially harmful gases as follows: Nitrous Oxide 100ppm Halogenated volatile anaesthetic agents 50ppm If Halothane is used 10ppm. The P3 Simplex and Duplex AGSS Plants are very easy to install. All plants have one inlet and one exhaust reducing the cost of installation. The inlet and outlet have flexible hose connections to reduce the transmission of noise down the pipework. They require one electrical supply. Either Single Phase Neutral and Earth or Three Phase Neutral and Earth. In addition, 24VAC remote control units can be installed in the operating rooms to control the Plant. This will require an additional 5 core control cable which can be linked in series to each remote control unit. As Standard, each Plant is fitted with a balance valve. The balance valve allows the pump to maintain a pressure of 150mbar when the flow changes within the system. The balance valve is protected from dirt and airborne particles by an Ingress Filter. P3 can offer complete systems which consists of AGSS Plant - Terminal Unit - Air Break - Patient Mask.

Surface/Flush Terminal Unit with NISTPendant Terminal Units (Rear-entry Barb)Pendant Terminal Units (90 degree Rear-entry NIST)Pendant Terminal Units (Rear-entry NIST)Rear Entry Bedhead Terminal UnitsRight Hand Bedhead Terminal UnitsLeft Hand Bedhead Terminal UnitsBedhead Terminal UnitsFlush/Surface Terminal Units

Surface/Flush Terminal Unit with NIST

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for flush or surface wall mounting, supplied with mounting box kit.

- Supplied with NIST connector 1st fix for connection to the pipeline system.

- Fully tested and certified prior to despatch.

Pendant Terminal Units (Rear-entry Barb)

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for vertical or horizontal mounting in pendants.

- Supplied with rear entry hose barb 1st fix for connection to the pipeline system.

- Fully tested and certified prior to despatch.

Pendant Terminal Units (90 degree Rear-entry NIST)

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for vertical or horizontal mounting in pendants.

- Supplied with 90° rear entry NIST connector 1st fix for connection to the pipeline system.

- Fully tested and certified prior to despatch.

Pendant Terminal Units (Rear-entry NIST)

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for vertical or horizontal mounting in pendants.

- Supplied with rear entry NIST connector 1st fix for connection to the pipeline system.

- Fully tested and certified prior to despatch.

Rear Entry Bedhead Terminal Units

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for mounting into bedhead trunking.

- Supplied with rear entry Ø12mm copper stub 1st fix for brazing into the pipeline system.

- Fully tested and certified prior to despatch.

Right Hand Bedhead Terminal Units

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for mounting into bedhead trunking.

- Supplied with 90° Ø12mm copper stub 1st fix for brazing into the pipeline system.

- Fully tested and certified prior to despatch.

Left Hand Bedhead Terminal Units

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for mounting into bedhead trunking.

- Supplied with 90° Ø12mm copper stub 1st fix for brazing into the pipeline system.

- Fully tested and certified prior to despatch.

Bedhead Terminal Units

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for mounting into bedhead trunking.

- Supplied with Ø12mm copper stub 1st fix for brazing into the pipeline system.

- Fully tested and certified prior to despatch.

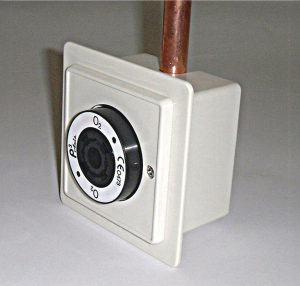

Flush/Surface Terminal Units

- Meets the requirements of HTM 02-01 and HTM 2022 – Medical Gas Pipeline Systems, BS EN ISO 9170-1, BS EN ISO 9170-2, BS 5682, BS 8532 and BS EN ISO 18082.

- Available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, AGSS, carbon dioxide and nitrogen.

- Suitable for flush or surface wall mounting, supplied with mounting box kit.

- Supplied with Ø12mm copper stub 1st fix for brazing into the pipeline system.

- Fully tested and certified prior to despatch.

AVSU Metal VersionAVSU with Pressure Sensors - Breakable WindowAVSU - Breakable WindowAVSU with Pressure Sensors - Emergency AccessAVSU - Emergency Access

AVSU Metal Version

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems and BS EN ISO 7396-1

- Available with 22mm, 28mm or 42mm valve and copper stubs, in a lockable steel enclosure

- Access to the valve assembly via key lock, or break window in emergency

- Equipped with BS EN ISO 18082 NIST Connectors

- Pressure sensors fitted as optional extra

- Suitable for flush or surface mounting

AVSU with Pressure Sensors - Breakable Window

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems and BS EN ISO 7396-1

- Available with 22mm or 28mm valve and copper stubs, in a lockable polymer enclosure

- Access to the valve assembly via key lock, or break window in emergency

- Equipped with BS EN ISO 18082 NIST Connectors

- Pressure sensors included for connection to area alarm panel

- Suitable for flush or surface mounting

AVSU - Breakable Window

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems and BS EN ISO 7396-1

- Available with 22mm or 28mm valve and copper stubs, in a lockable polymer enclosure

- Access to the valve assembly via key lock, or break window in emergency

- Equipped with BS EN ISO 18082 NIST Connectors

- Suitable for flush or surface mounting

AVSU with Pressure Sensors - Emergency Access

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems and BS EN ISO 7396-1

- Available with 22mm or 28mm valve and copper stubs, in a lockable polymer enclosure

- Access to the valve assembly via key lock, or emergency release lever

- Equipped with BS EN ISO 18082 NIST Connectors

- Pressure sensors included for connection to area alarm panel

- Suitable for flush or surface mounting

AVSU - Emergency Access

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems and BS EN ISO 7396-1

- Available with 22mm or 28mm valve and copper stubs, in a lockable polymer enclosure

- Access to the valve assembly via key lock, or emergency release lever

- Equipped with BS EN ISO 18082 NIST Connectors

- Suitable for flush or surface mounting

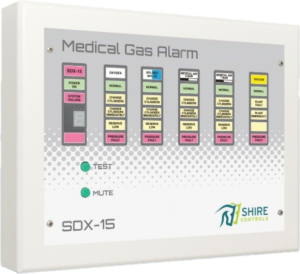

Area Alarms

Area Alarm Panels are used to monitor pipeline pressure within various wards and departments, are suitable for up to 6 gases and can be flush or surface mounted.

Plant Alarms

The plant alarm system is used to monitor the status of the primary supply manifolds, plant and/or bulk liquid supplies.

The alarm panels are suitable for up to 15 gases and can be flush or surface mounted.

The alarms meet the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

Line Valves

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- 15mm – 108mm sizes available.

- Flat face unions between stubs and valve incorporating o-ring seals for gas tight connections.

- Valve handle is lockable in the open or closed position to prevent unauthorised or inadvertent valve operation.

- 100% tested for leaks to atmosphere and isolation when in the closed position.

NIST Line Valves

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- 15mm – 108mm sizes available.

- Flat face unions between stubs and valve incorporating o-ring seals for gas tight connections.

- Valve handle is lockable in the open or closed position to prevent unauthorised or inadvertent valve operation.

- Supplied with EN ISO 18082 NIST connectors.

- 100% tested for leaks to atmosphere and isolation when in the closed position.

Non-return Valves

- Meets the requirements of HTM 02-01 & HTM 2022 - Medical Gas Pipeline Systems.

- 15mm – 108mm sizes available.

- Flat face unions between stubs and valve incorporating o-ring seals for gas tight connections.

- 100% tested for leaks to atmosphere.